Debond and ACP Bond

Composite panels (sandwich panels) made of aluminum sheets and a mineral or polyethylene core are ideal for the production of advertisements. Debond and ACP Bond often called Dibond boards.

Product sorting

List of products

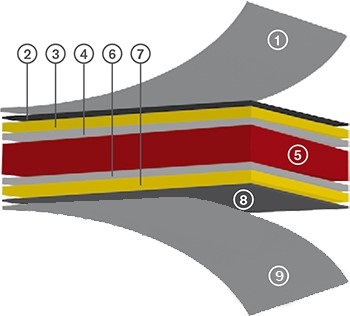

Composite panels (sandwich panels) DeBond and ACP Bond with aluminium cover layers and polyethylene or mineral core suitable not only for signmaking but also for construction. Surface treatment PVDF (polyvinyl chloride paint) or polyester paint with the possibility of ordering according to RAL. DeBond composite boards are characterised by their very low weight, high stability, excellent weather resistance and perfectly smooth surface. DeBond composite panels can be ordered in thicknesses from 2 to 4 mm and aluminium thicknesses from 0.12 to 0.5 mm. If required, we can adjust to your desired dimensions.

Specifications

Features:

- Sandwich board with polyethylene (PE) or mineral core

- Possibility of fine radius permanent bending

- PVDF (polyvinyl chloride paint) or polyester paint finish

- Minimal expansion, no warping

Permanence of colour:

- Polyester varnish - not specified

- PVDF - colour fastness 10 years

- HDPE – color more resistant to UV radiation (more saturated, more stable, and longer lasting)

Advantages:

- perfectly smooth and even surface

- wide range of RAL colours and designs, imitation of natural materials, metallic, brushed

- possibility of advertising printing, digital printing, screen printing, paint painting, lamination

- high bending and breaking strength, vibration damping - no need for anti-vibration treatment

- dimensional stability, easy handling

- easy machinability by conventional methods, recyclable

Warning:

There may be colour differences between RAL codes and the actual colour of the aluminium composite panels! For application, it is essential to follow the installation instructions, and it is essential to follow the positioning of the panels so that the arrows shown on the foil are superimposed and applied in the same direction.

Differences in characteristics:

Each product has certain properties and characteristics that may vary slightly from batch to batch. Exceptionally, however, within a batch. It is recommended that these characteristics be taken into account when designing the project.

Cut of material:

|

|

| Width (mm) |

Length (mm) |

Thickness (mm) |

Al sheet thickness (mm) |

Noise isolation (dB) |

Fireproof class | Heat resistance (°C) |

Color |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 3 | 0,12 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 3 | 0,18 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 2 | 0,21 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 3 | 0,21 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 3 | 0,30 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 4 | 0,30 | 25 | E | -50 to +80 | dle RAL |

| 1000 – 1220 – 1500 – 2000 | 3000 – 6000 | 4 | 0,50 | 25 | E | -50 to +80 | dle RAL |

| Width (mm) |

Length (mm) |

Thickness (mm) |

Al sheet thickness (mm) |

Noise isolation (dB) |

Fireproof class | Heat resistance (°C) |

Surface | Color |

| 1000 – 1250 – 1500 | 3000 – 6000 | 3 | 0,3 | 25 | E | -50 to +80 | PES |

according to RAL |

| 1000 – 1250 – 1500 | 3000 – 6000 | 3 | 0,4 | 25 | E | -50 to +80 | PES | according to RAL |

| 1000 – 1250 – 1500 | 3000 – 6000 | 4 | 0,4 | 26 | A2 – fireproof | -50 to +80 | PVDF, Nature ART Design, Brushed, Mirror | according to RAL |

| 1000 – 1250 – 1500 | 3000 – 6000 | 4 | 0,4 | 26 | B1 (FR) – fire resistant | -50 to +80 | PVDF, standard, metallic, brushed | according to RAL |

| 1000 – 1250 – 1500 – 2000 | 3000 – 6000 | 4 | 0,4 | 25 | B2 (PE) – not fire resistant | -50 to +80 | PES, standard, metallic, brushed | according to RAL |

| 1000 – 1250 – 1500 | 3000 – 6000 | 4 | 0,5 | 26 | A2 – fireproof | -50 to +80 | PVDF, Nature ART Design, Brushed, Mirror | according to RAL |

| 1000 – 1250 – 1500 | 3000 – 6000 | 4 | 0,5 | 26 | B1(FR) – fire resistant | -50 to +80 | PVDF, standard, metallic, brushed | according to RAL |

| 1000 – 1250 – 1500 – 2000 | 3000 – 6000 | 4 | 0,5 | 25 | B2 (PE) – not fire resistant | -50 to +80 | PES, standard, metallic, brushed | according to RAL |

Use:

- for facade cladding and mechanically extremely stressed advertising

- Suitable for outdoor use (facades) with PVDF (polyvinyl chloride paint) surface treatment, 5 to 10 years warranty.

- for printing, laminating

- building cladding, building infill, inside of cells, substrate for advertisements

- for builders we have a support structure, S and Z profile, folded into a cassette assembly

Processing:

- milling and partial milling (aesthetically high-quality 3D objects can be produced)

- cutting

- bending on roller bending machines

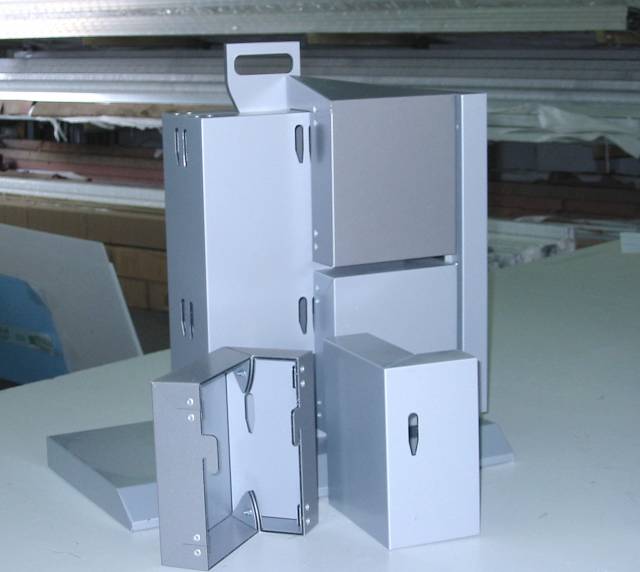

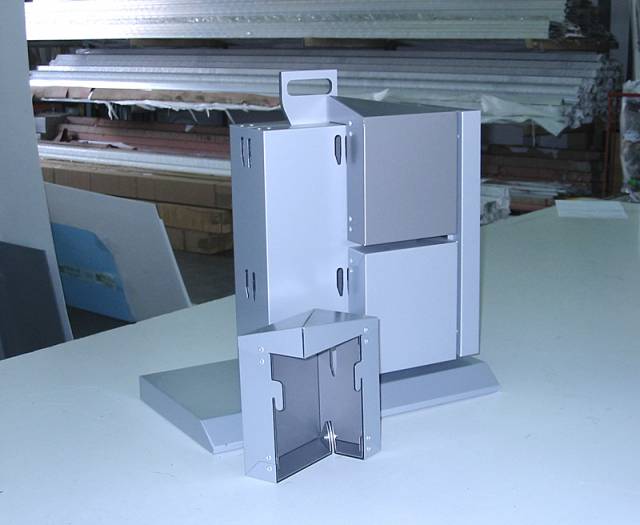

Examples of processing

The Debond material can be processed and subsequently assembled into three-dimensional objects. The individual photographs illustrate alternative applications for this material, which can be folded, bent, riveted, bolted, glued or joined in a non-contact way in a puzzle system.

Also shown is the possibility of using it without the need for substructure, where the individual parts are anchored to each other. This applies to applications in smaller areas of up to a few m2 - for applications such as building envelopes in ventilated façade systems, the use of a substructure is necessary. Machining with a milling machine is possible in dimensions of 2000 x 6000 mm with a machining accuracy of 0.05 mm - the cassette (product) after assembly is within a dimensional tolerance of 0.5 mm. In the opposite spectrum, business card-sized products can be produced. The material is intended for use in construction, engineering, automotive, design, advertising and the production of decorative elements.

-1.jpg?68d3d670)